Medical Manufacturing

In addition to design, engineering and prototyping services, we offer a fully managed manufacturing service, saving the client time, travel and associated difficulties and costs of working with overseas vendors.

We have been manufacturing products for over a decade. These projects range from high volume runs of over a million units, to lower volume, high value medical devices. Each project is different, and our Hong Kong and China based teams work closely with a wide range of vendors to ensure that we can facilitate any industry-specific needs.

For example, many medical products must comply with strict regulatory standards. The carefully selected contract manufacture facilities which we partner with are compliant with ISO 13405, ISO 9001 and ISO 140001 to name a few, and products can even be manufactured or packed out in an ISO class 8 (100,000) clean room. Moreover, process validation via a QC process consisting of IQ, OQ and PQ ensures risk reduction, improving overall manufacturing efficiency. We also has invaluable experience working with recognised 3rd party laboratories for compliance testing and product certification.

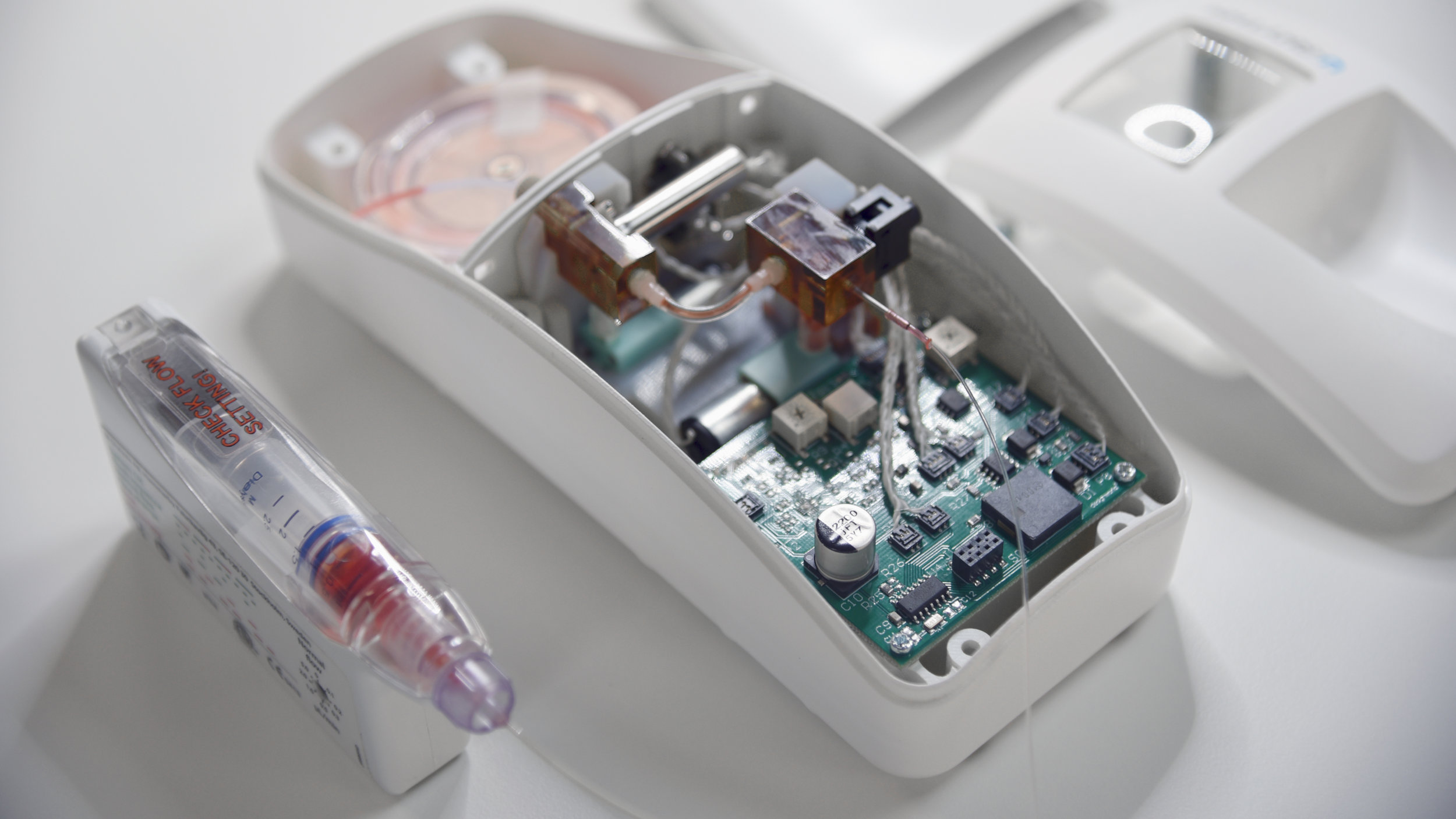

One medical project which utilised the full end-to-end service was the fluid warming device, designed and manufactured by Designworks for Celsius Medical. The client approached Designworks with a brief and left with market-ready injection moulded products. The project progressed through from ideation and concept development to 3D CAD data generation, design for manufacture, toolmaking and debug before finally being moulded in the Far East. It is now an industry leading solution for medical fluid warming.

Other projects demanded a more local approach, and we have mass manufactured products for Clarks International in the UK and even handle ongoing warranty support from our Windsor headquarters.

We aim to make the development of medical products cost-effective, quick and simple. A truly end-to-end and fully managed service means that products are developed efficiently and progress to manufacture seamlessly. Furthermore, a wealth of experience working to relevant ISO standards and medical-specific requirements has elevated us to the forefront of medical product manufacturing.