Modelshop case study - BP Alternative Energy

Any colour you like, as long as it’s metallic…

In recognition of the new modelshop.studio site going live last week, we’ve been speaking to some of the team about their favourite jobs over the years and thought it might be nice to spotlight some over the coming weeks and to dig a bit deeper for a few details.

This week we’re looking back at one of numerous projects we’ve done with BP, in this case to help demonstrate how their alternative energy infrastructure works. Just a couple of years old now, it’s a subject that’s become all the more timely since then as countries across Europe urgently focus on securing new sources of energy.

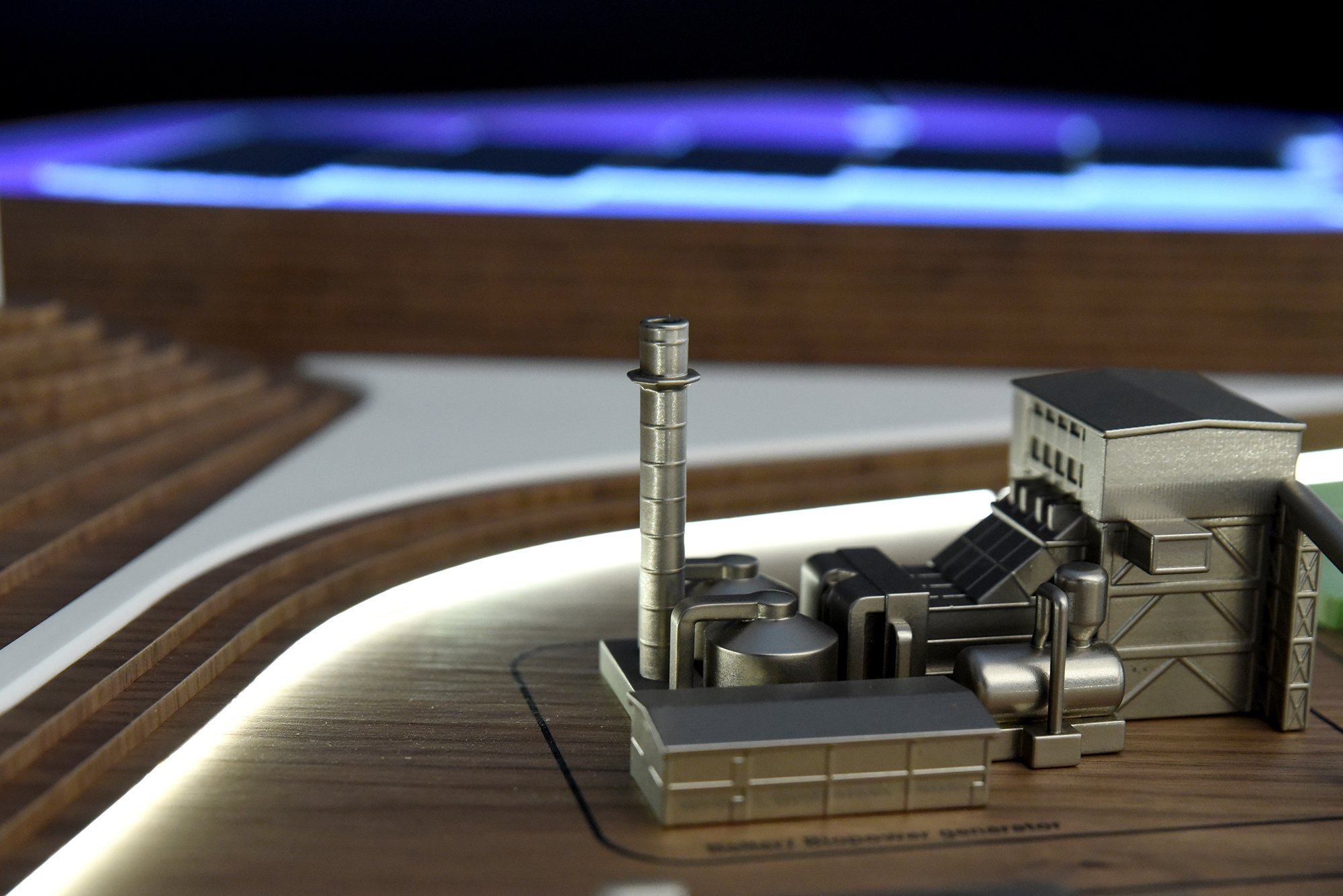

A look and feel for our BP models had evolved and been established over the preceding eight years, and this one called-on that same aesthetic of matte white with contrasting dark wood, so was a great fit for a model that was a freestanding ‘tabletop’ akin to a piece of furniture. “Most of what you notice on first impression is the HIMACS and the walnut veneer” Both materials used in furniture, they give a familiar feeling combined with a durable finish.

Beneath this robust surface, there were electronics cleverly concealed to provide illumination to represent a reservoir, and to power a field of five tiny wind turbines about a 400th of their actual size - each with it’s own illumination for any tiny aircraft that might be flying by.

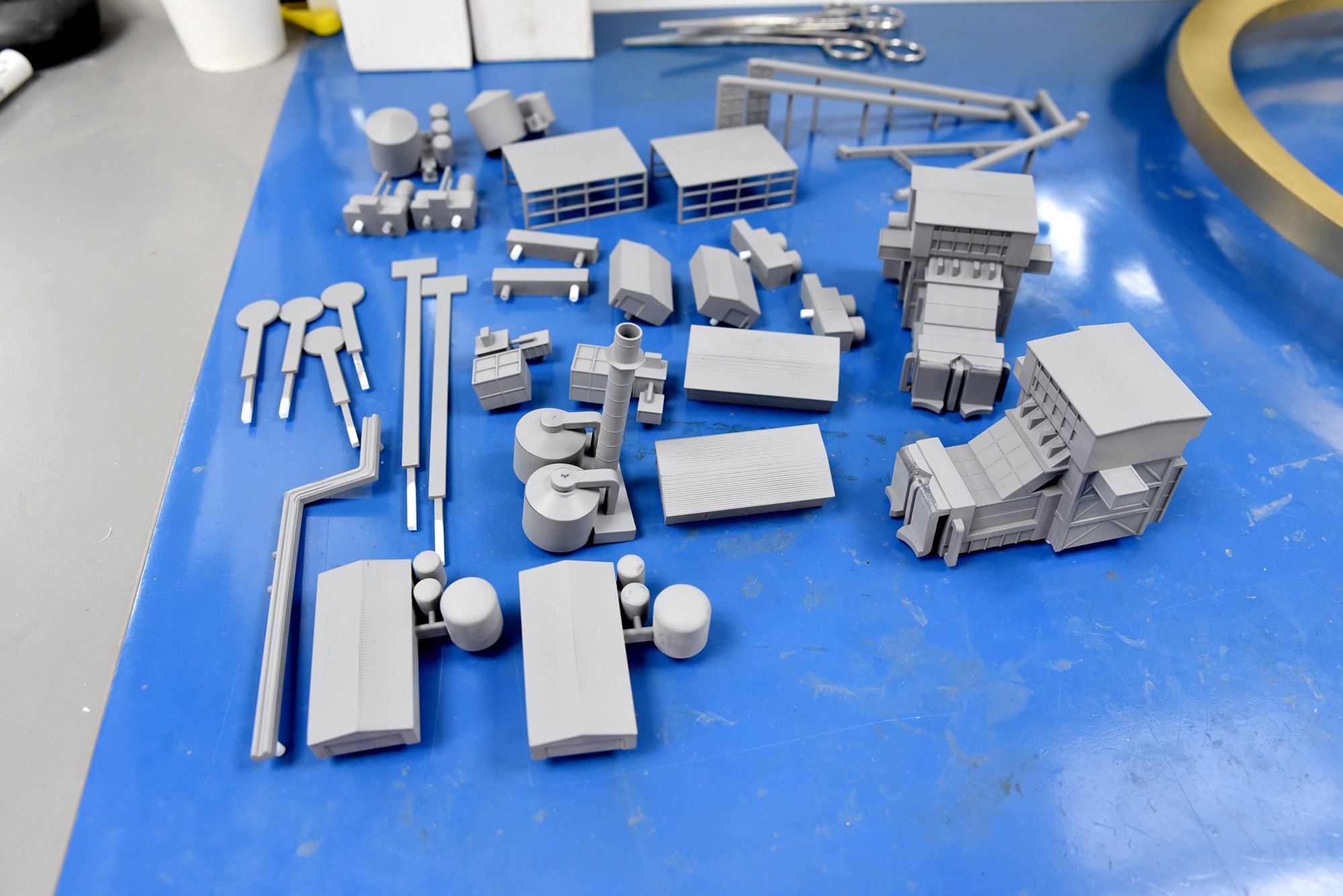

The various buildings around the site are 3D prints that have been electroplated with nickel. “What was fun here was we got to use some more tried and tested processes, and to try out some things that were new to us” Accordingly this time the parts were then vapor blasted to achieve a satin finish. This is in contrast to some of modelshop’s other electroplating and metallic painting jobs for bespoke trophies, where a high-gloss finish is the name of the game. Take a look at the images and titles below to see some of the processes we’ve used and let us know below if you’ve any comments or questions about these processes…

A laser-engraved aluminium plate, and some tiny custom rubdowns were the finishing touches to help lift the BP model and make explicit the meaning of all the different elements.

Here it is at home in BP’s offices in St. James’ Square, London.

To find out more about modelshop’s experience and capability with models like this, find them at modelshop.studio and in this month’s Architects Journal.